Description

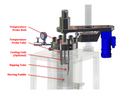

A complete set of high pressure chemical reactor

Stainless steel frame/furnace system with temperature controller

Reactor sealing using flange with PTFE or grafoil gasket

Swagelok needle valve and VivTek fittings installed (pressure gauge)

Gas port and liquid dipping tube port using Swagelok needle valves

Electrical heating furnace built-in

Magnet coupled stirring device with cooling jacket (Circulation pump included)

Motor AC220V 3P 200W, 2800RPM (stirring speed 50-1200RPM)

Vessel construction SUS316L standard, other materials per quoted

Digital control system with temperature, speed and timing control functions

Powered lifting device with hand controller

Stirring Speed: <1200RPM

Stirring paddles or impeller available or as requested

Temperature <350℃

Pressure <20Mpa/2900psi

7-inch touch screen PLC/HMI controller with remote control (EasyAccess 2.0)

Stainless steel frame/furnace system with temperature controller

Reactor sealing using flange with PTFE or grafoil gasket

Swagelok needle valve and VivTek fittings installed (pressure gauge)

Gas port and liquid dipping tube port using Swagelok needle valves

Electrical heating furnace built-in

Magnet coupled stirring device with cooling jacket (Circulation pump included)

Motor AC220V 3P 200W, 2800RPM (stirring speed 50-1200RPM)

Vessel construction SUS316L standard, other materials per quoted

Digital control system with temperature, speed and timing control functions

Powered lifting device with hand controller

Stirring Speed: <1200RPM

Stirring paddles or impeller available or as requested

Temperature <350℃

Pressure <20Mpa/2900psi

7-inch touch screen PLC/HMI controller with remote control (EasyAccess 2.0)

| Model | Volume |

Pressure | Dimensions | Voltage |

| HiPR-SF1L |

1000mL | <20MPa | 55x60x150cm | AC230V |

| HiPR-SF2L |

2000mL | <20Mpa | 55x60x150cm | AC230V |

| HiPR-SF5L |

5000mL | <20MPa | 60x75x175cm | AC230V |

| HiPR-SF10L | 10L | <20MPa | 75x80x175cm | AC230V |